Mugihe twegereye 2025, inganda zikora ziri hafi guhinduka, biterwa niterambere ryikoranabuhanga rya CNC. Kimwe mu bintu bishimishije cyane ni izamuka rya nano-precision mu gusya kwa CNC, isezeranya guhindura uburyo ibice bigoye kandi bisobanutse neza. Iyi myumvire biteganijwe ko izagira ingaruka zikomeye mubice bitandukanye, birimo ibinyabiziga, icyogajuru, ibikoresho byubuvuzi, na elegitoroniki.

Nano-Precision: Imipaka ikurikira muri CNC Milling

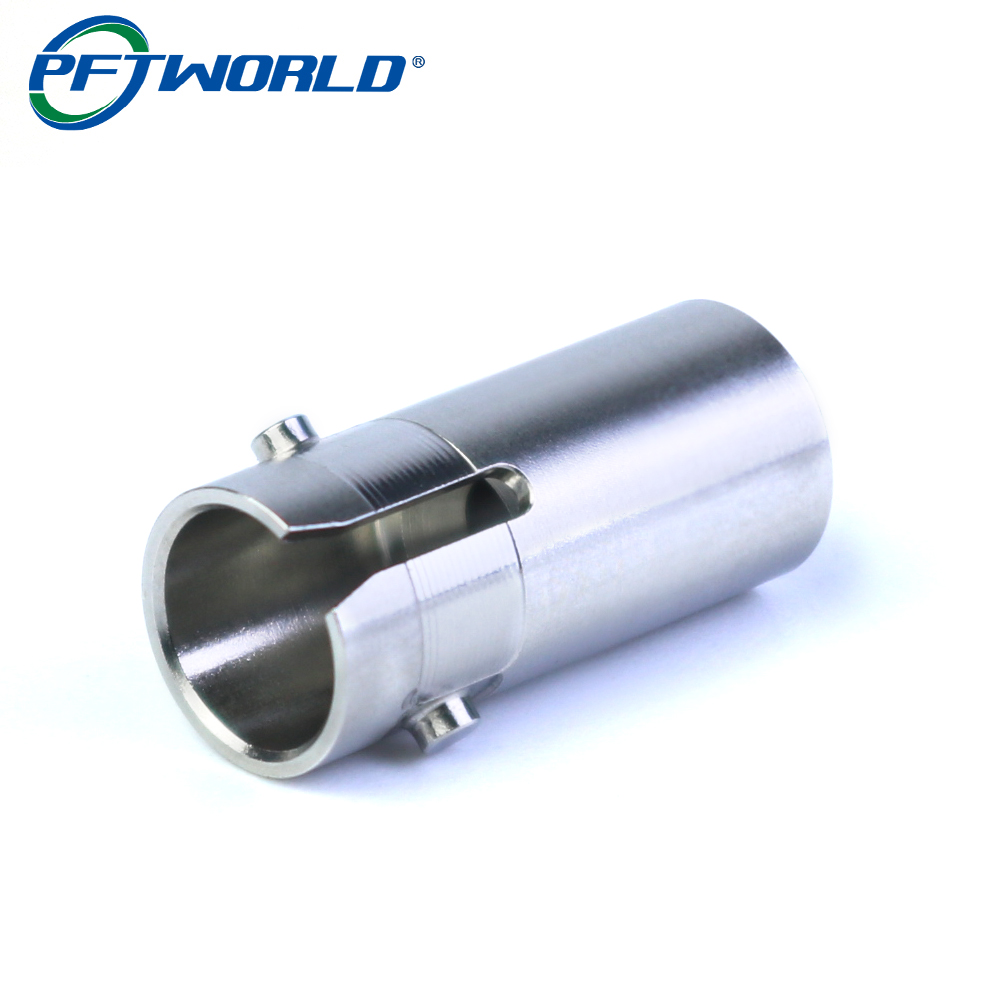

Nano-precision mu gusya kwa CNC bivuga ubushobozi bwo kugera kurwego rwo hejuru cyane rwukuri kurwego rwa nanometero. Uru rwego rwibisobanuro ningirakamaro mubikorwa byo gukora hamwe na geometrike igoye kandi yihanganirana cyane, bigenda bisabwa ninganda zigezweho. Mugukoresha ibikoresho bigezweho, ibikoresho bigezweho, hamwe na software ihanitse, imashini zisya CNC ubu zirashobora gukora ibice bifite ubunyangamugayo butagereranywa.

Iterambere ryingenzi Gutwara Nano-Precision

1.Kwishyira hamwe kwa AI hamwe no Kwiga ImashiniUbwenge bwa artificiel (AI) hamwe no Kwiga Imashini (ML) bigira uruhare runini mukuzamura ubusobanuro bwa CNC. Izi tekinoroji zifasha imashini kwigira kubikorwa byashize, guhitamo inzira zo guca, no guhanura kwambara, bityo bikagabanya amakosa no kunoza imikorere. Sisitemu ikoreshwa na AI irashobora kandi gukora igihe nyacyo cyo guhindura, kwemeza ko buri gikorwa cyo gutunganya cyujuje ubuziranenge bwo hejuru.

2.Ibikoresho bigezweho hamwe no gukora HybridGukenera ibikoresho byoroheje ariko biramba nka titanium alloys, ibinyabuzima bya karubone, hamwe na polymers zikomeye cyane bituma hakenerwa ubuhanga buhanitse bwo gutunganya. Urusyo rwa CNC rugenda rutera imbere kugira ngo rukoreshe ibyo bikoresho bigezweho kandi neza, tubikesheje udushya mu gukoresha ibikoresho no gukonjesha. Byongeye kandi, guhuza inganda ziyongera (icapiro rya 3D) hamwe no gusya CNC ni gufungura uburyo bushya bwo gukora ibice bigoye hamwe no kugabanya imyanda yibikoresho.

3.Automation na RoboqueAutomation ihinduka urufatiro rwo gusya CNC, hamwe nibikorwa bya robo bikora imirimo nko gupakira, gupakurura, no kugenzura igice. Ibi bigabanya amakosa yabantu, byongera umusaruro, kandi bituma 24/7 ikora. Imashini za robo (cobots) nazo ziragenda ziyongera, zikorana nabakozi bakora kugirango bongere umusaruro.

4.Imyitozo irambyeKuramba biragenda byiyongera mubikorwa, kandi gusya CNC nabyo ntibisanzwe. Abahinguzi barimo gukoresha ibidukikije byangiza ibidukikije nkimashini zikoresha ingufu, ibikoresho bisubirwamo, hamwe na sisitemu yo gufunga ibicuruzwa kugirango bigabanye ingaruka z’ibidukikije. Ibi bishya ntabwo bigabanya imyanda gusa ahubwo binagabanya ibiciro byakazi, bituma urusyo rwa CNC rurambye kandi ruhendutse.

5.Impanga ya Digital hamwe no kwigana ibintuIkoranabuhanga rya twin-tekinoroji-ikora kopi ya sisitemu yumubiri-ituma abayikora bigana uburyo bwo gusya CNC mbere yumusaruro. Ibi byerekana neza imashini igenamigambi, igabanya imyanda yibikoresho, ikanagaragaza ibibazo bishobora kubaho mbere, biganisha ku busobanuro bunoze kandi bunoze.

Ingaruka ku nganda zingenzi

•Imodoka.

•Ikirere: Ubushobozi bwo gukoresha ibikoresho bigezweho kandi bisobanutse neza bizaba ingenzi mugukora ibice bigoye nka turbine blade nibice byubaka indege.

•Ibikoresho byo kwa muganga: Gusya cyane-CNC gusya bizagira uruhare runini mugukora ibicuruzwa byabigenewe, ibikoresho byo kubaga, nibikoresho byo gusuzuma, kuzamura ibisubizo byabarwayi no kuvura neza.

•Ibyuma bya elegitoroniki: Inzira iganisha kuri miniaturizasi muri electronics izungukira kuri nano-precision, ituma abayikora bakora ibintu bito, bikomeye.

Kwiyongera kwa nano-precision mu gusya kwa CNC bigiye gusobanura neza imipaka y'ibishoboka mu nganda. Mugukoresha AI, ibikoresho bigezweho, hamwe nibikorwa birambye, gusya CNC bizakomeza guteza imbere udushya no gukora neza mubikorwa bitandukanye. Iyo turebye imbere muri 2025, ahazaza h'inganda hasa neza kandi neza kuruta mbere hose.

Igihe cyo kohereza: Werurwe-12-2025